PRG 2021 Release; FEPipe, NozzlePRO, FEATools

The new version of the PRG Finite Element Analysis (FEA) software suite has been released. PRG 2021 contains FEPipe v15.0, NozzlePRO v15.0 and FEATools v15.0

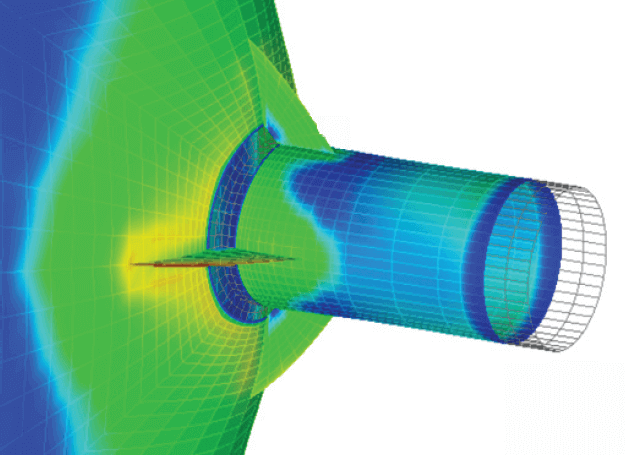

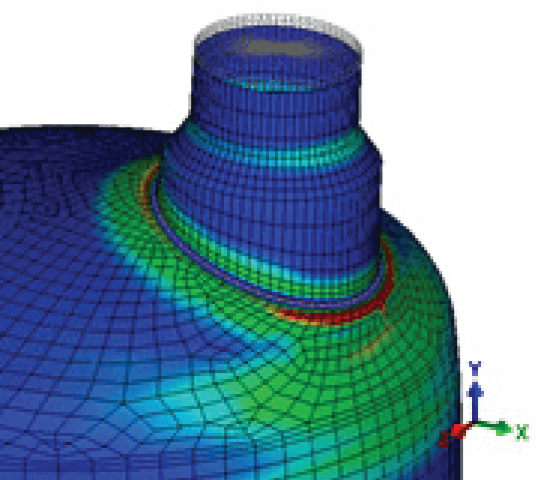

NozzlePRO is a dedicated software solution for piping and pressure vessel components. It brings the accuracy of the Finite Element Analysis (FEA) to the engineering community for general design and analysis. The software is based on the technology offered in FEPipe with a user interface that simplifies input and allows engineers to quickly analyze piping and pressure components with a high degree of accuracy.

NozzlePRO is part of the PVPT (Pressure Vessel Piping and Tank) Design Suite.

More than 30 years of experience with surge analyses have been incorporated into NozzlePRO.

We are committed to continue doing so in every new version of the software.

NozzlePRO can perform automatic fatigue calculations to comply with piping and pressure vessel design codes. NozzlePRO contains the following modules:

NozzlePRO also provides piping elements to evaluate the effect of pipe thermal expansion on the nozzles. This capability results in a much more accurate evaluation of loads and displacements on the nozzle and in the piping system. Straight sections, elbows, bends, intersections and linear restraints may be included in the analysis.

The technology incorporated in NozzlePRO is a significant improvement over the limitations inherent in WRC 107/297 methods. WRC methods are only accurate across a small subset of ranges found in industrial applications, whereas NozzlePRO is mainly constrained by the geometry of the component to be modeled.

The software is designed to quickly and easily evaluate nozzles, saddles, pipe shoes and clips according ASME VIII Division 2. A variety of head types are allowed including spherical, elliptical, ASME, dished, cylindrical and conical. A minimum number of values must be input to generate the model. The engineer is able to include thermal, weight, operating, occasional, pressure, wind and earthquake loads. The output is shown using comprehensive ASME code compliance reports.

NozzlePRO accounts for thermal, weight, operating, occasional, pressure, wind and earthquake loads so that compliance requirements can be easily determined and met.

The new version of the PRG Finite Element Analysis (FEA) software suite has been released. PRG 2021 contains FEPipe v15.0, NozzlePRO v15.0 and FEATools v15.0

There has been a demand for Online FEPipe and NozzlePRO training courses for many years. We are happy to announce that next month we will

Laan van Oversteen 20

6th floor

2289 CX Rijswijk

The Netherlands

© Dynaflow Research Group BV